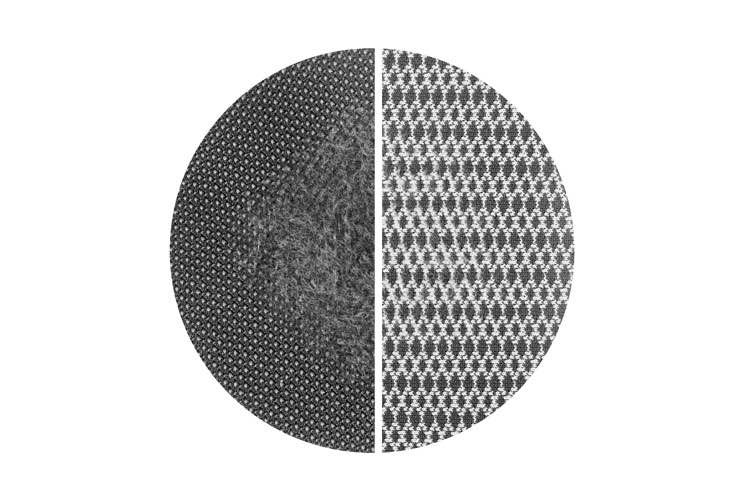

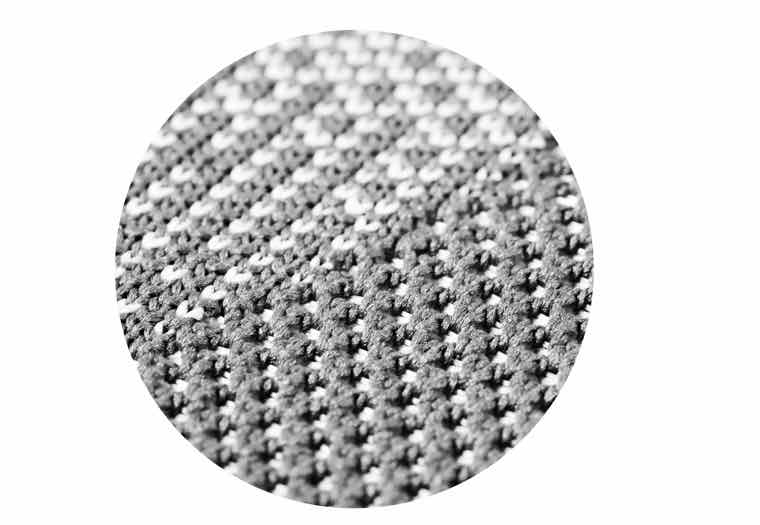

Bobingen - A collaboration between polyester yarn manufacturer Trevira and development services company imat-uve has resulted in a new 3D flat knitting method for the production of anatomically contoured seat covers and trim components for vehicle interiors.

Described by the companies as a "milestone in textiles design", the jointly developed process is said to offer a combination of the latest yarn technologies and cutting-edge connection and finishing techniques.

One of the key selling points of this new process appears to be how the technology uses just one knitting process rather than several, which, in theory, will allow manufacturers to reduce their production and materials costs, as it's no longer necessary to cut and assemble the fabrics.

However, the new invention is not just cost-effective – the flat knitting technique means that it's now possible to personalise design and function to a much greater degree, representing a major step in the direction of on-demand production.

Trevira and imat-uve claim to be the first companies to develop such a sophisticated application of the knitting process for use in vehicles, made possible by imat-uve’s processing and finishing technique which deploys a low-melt yarn specifically developed by Trevira. The collaboration has resulted in a high-performing knitted product which satisfies even the most demanding criteria in terms of quality and comfort, the companies say.

Specifically, the VDA 230-210 standard velcro test carried out by imat's testing laboratory found that the product was extremely abrasion resistant. The 3D flat knitting technology even means that areas known to be vulnerable, such as the seams on seat covers, can be strengthened in the course of the same single knitting process. Another benefit of the technology is its contribution to sustainable manufacturing. Not only does it work on the zero waste principle, but the knitted fabric itself is manufactured entirely from yarn made from PES recyclates.

Thomas Rademacher, Head of Development at Trevira, explains why the collaboration was so successful. "The development company imat-uve came up with a new breakthrough technology, while here at Trevira, we contributed our own recycled yarns and a new low-melt yarn we've developed based on synthetic fibres, which provides a stabilising effect. Together we have created a highly sought-after, top quality product for automotive interiors. Flat knitting will now be the go-to technology for vehicle interiors – in the future, it will be impossible to imagine life without it."

Hans Peter Schlegelmilch, imat-uve’s CEO, pointed out the especial benefits of the new technology for vehicle manufacturers and their suppliers. "The 3D flat knitting technology doesn't just make it possible to save time and money on production. It also opens up a whole new world of personalisation for end consumers. We are extremely pleased that with Trevira as our partner, we have been able to take this significant step towards the future of automotive interiors."

Trevira

Trevira GmbH is a European manufacturer of high-value branded fibres and filament yarns for technical applications and hygiene products as well as for home textiles, automotive interiors and functional apparel. Two production sites and a Marketing and Sales office with a total of approximately 1,100 employees are located in Germany and supplemented by an international marketing and sales organization.

The head office of the company is located in Bobingen near Augsburg although the company is owned by Indorama Venture PCL, Thailand.

imat-uve group gmbh is a design and engineering company which has positioned itself internationally as a strategic partner of the textile and automotive industry in recent years.

In addition to its headquarter in Mönchengladbach, the company also has additional branches in Germany, China, USA and South Africa, all of which are certified according to the high quality requirements of DIN EN ISO 17025, VDA 6.2., as well as ISO 9001.

The services accompany the entire value-added process from the idea to the finished component or product. This includes the design, development and testing of materials, components and systems.