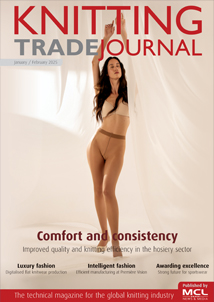

Obertshausen - Warp knitting machine builder Karl Mayer has been demonstrating the flexibility of its latest raschel knitting technology with a new collection of stylish 'sloungewear'.

"If we want to relax and unwind, we put on something comfortable, such as a big jumper, baggy pants or even our nightwear," says Karl Mayer. "The pyjama look has been popular for wearing as daywear for some time now, and is inspiring creative designers in the fashion sector to come up with hybrid styles that are invigorating the market."

Sloungewear is one of the latest products to emerge from this imaginative crossover sector, i.e. comfortable, on-trend clothing that combines leisurewear with nightwear. This mix of styles starts with the design, as illustrated by the set shown on this page. The top and shorts set combines the styling of pyjamas with a pattern typical of outerwear. The all-over lace was produced on a Lace.Express. It features floral motifs in a geometric arrangement and a large, striking pattern, which can only be produced on machines having a large number of guide bars.

An OJ 83/1 B with a gauge of E 24 was used to produce it. This flexible, multibar raschel machine worked a ground featuring a variety of patterns next to each other, comprising open, organic structures and filigree mesh areas. The contrasting effects in the ensemble are enhanced by using matt, textured and untextured, shimmering polyamide.

This eye-catching, dynamic look was designed by Neil Thorpe with the Chinese company, Dongyang Hongji Industry, supplying the yarn.

The first model of this machine series, the OJ 59/1 B, was only premiered at the end of 2016 and orders are already running into the high double-digit range. Up to 20 machines are leaving Karl Mayer’s assembly line for a number of projects, destined for a wide range of buyers including a mixture of new companies who are changing over from using machines produced by other manufacturer, and existing customers, many of whom are placing follow-up orders.

The latest edition of the Lace.Express range has a working width of 210 ins, and can reach the same high operating speed as the OJ 59/1 B. However, increasing the number of guide bars compared to the first Lace.Express machine means that more patterns can now be produced. In particular, being able to work picot patterns also makes the new machine interesting for producers of tapes and ribbons for intimate apparel.