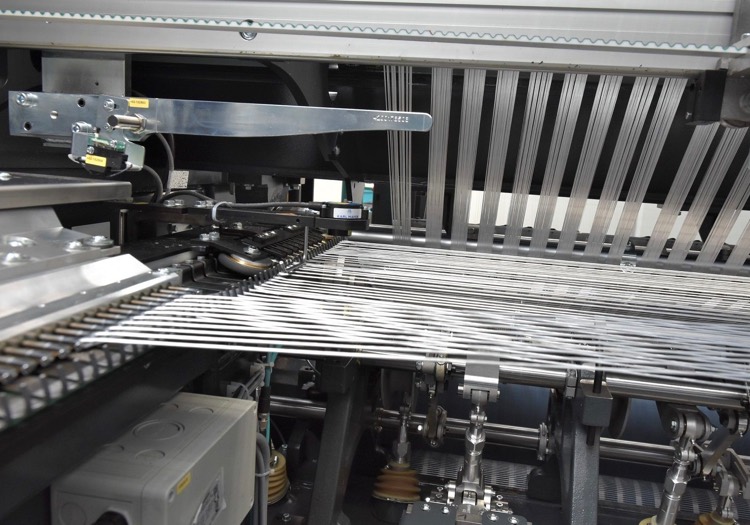

Obertshausen Karl Mayer Technical Textiles has launched the latest version of its Wefttronic technology, which includes a series of upgrades aimed at improving patterning possibilities and the operating efficiency of the whole system.

The company presented its best-selling Wefttronic II G at the recent ITMA exhibition where, according to Hagen Lotzmann, vice president, sales at Karl Mayer, the response to the machine was very enthusiastic with the number of visitors surprisingly high.

Visitors were particularly keen to discover the machines latest features which include the Vario Weft laying system, a new solution for stabilising the edges, monitoring of the weft tension and a central suctioning device.

The Wefttronic II G was shown in a working width of 213 ins, which is regarded as the best-selling working width for the production of geogrids.

Patterning freedom

The Vario Weft has been designed to makes changes of the weft pattern extremely simple, fast and flexible. This electronic solution requires no mechanical intervention during threading-in and has no limitations in terms of repeat length. There is also considerably less selvedge waste.

The basis for this advantage package is a newly developed patterning principle. Whereas the weft carriage and transport chain used to work with a weft insertion according to the desired pattern, now a full threading-in is always used.

A stop-and-go operation of the transport chain and a new movement curve of the supporting sinker ensure that the yarn is fed according to the pattern. If a weft yarn is to be inserted into the fabric, it is guided to the knitting elements by the circulating transport chain and brought into the engagement area of the slider needles by the supporting sinker.

If a free space is to be created in the fabric, the transport chain stops and the supporting sinker dips under the weft yarn. "The flexibility which Vario Weft offers in weft patterning is completely new for our customers," said Lotzmann.

"In discussions, potentials were discussed and thought processes initiated. We are expecting many new product ideas, and we will be on hand to help our customers implement them."

Environmental

With the elimination of the vacant positions in the transport chain, the waste generated here is also eliminated. In the conventional process, the weft yarns are passed by the empty positions, and the yarn sections running in the direction of work have to be disposed of, with negative effects on costs and the environmental balance.

The relative yarn waste is greater the more positions have to be bridged and weft threads inserted, i.e. the more open the grid is. When considering the absolute savings potential, however, the count of weft yarns in the fabric must also be taken into account.

For example, with a weft threading in of 5 full, 10 out, about 61% less material is needed. This results in a cost saving of about € 38,000 and about 256,000 kg less CO2 emissions per year. In the case of denser grid designs with an threading-in of 2 full, 2 out, the material saving is lower at just under 46%, but the absolute annual saving in costs is higher at around €40,000 and almost 270,000kg in CO2 emissions.

Stable selvedges

A further new feature of the Wefttronic II G stabilises the fabric selvedges and uses the weft yarn ends for this purpose. The weft yarn ends sticking out at the sides of the mesh selvedges are mechanically, and by means of airflow, returned to the warp knitting elements and firmly integrated into the mesh structure by means of a stitch.

Due to the consolidated fabric ends, the grids can be better fixed during the finishing process - which is an advantage for the production of medium-weight and heavy geotextiles. This allows the shrinkage behaviour of the warp knitted fabric to be adjusted in a controlled manner and its quality to be improved. The consolidated selvedge structures can also open up new areas of application, for example in the fields of slope stabilisation and safety nets.

Controlled yarn tension

To maximise fabric quality, this latest version has also been equipped with a weft tension monitoring system. The new solution keeps an eye on every single yarn and triggers actions when threshold values are exceeded or undershot: first a warning, then the machine is stopped.

When resetting to new patterns, the weft tension can be easily adjusted and controlled, thereby improving the reproducibility of the product quality. In addition, the tension data can be stored for control and traceability of production orders.

A new device for suctioning off selvedge waste meanwhile, the CSD 600, focuses on increasing machine efficiency.

This system continuously picks up the weft waste during machine operation and uses operational stops for fully automatic emptying, without any manual intervention. In addition, less electrical energy is required compared to the previous solution with one suction cabinet on each side of the machine. The savings potential is around 8%, Karl Mayer says.