Reutlingen - Flat knitting machine builder Stoll, part of the Karl Mayer Group, has been working with Indorama Ventures and dyeing specialist DyeCoo on a groundbreaking, sustainable facemask project.

As we enter the second year of the worldwide Covid-19 pandemic there is a continuing need for masks. However, while facemasks help greatly in mitigating the spread of the virus and protecting the wearer, they also contribute to environmental problems such as waste and pollution.

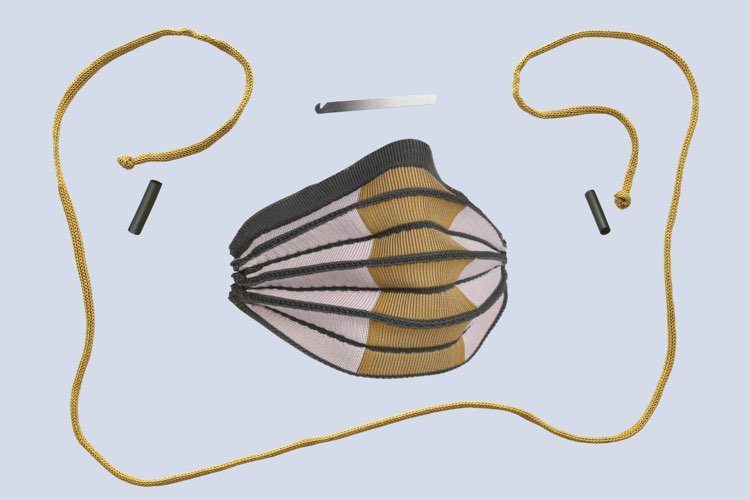

Easy Mask is a collaborative initiative between Indorama Ventures, DyeCoo and Stoll to produce a fashionable mask with a sustainable mind-set throughout the whole production process - starting from the yarn production and followed by the dyeing, design and production.

With the advanced technologies of the three companies, the mask does not just eliminate waste, but also reduces the use of water and energy. The design approach also ensures that all components can be easily removed and re-used for other masks.

The raw material used in the Easy Mask production process is Indorama's Deja, which is a sustainable, recycled polyester. This polyester performance yarn is made from 100 per cent post-consumer recycled PET bottles and can be used for a multitude of home and apparel applications. The yarn is independently certified and traceable, with full transparency across raw material and processes including GRS, Ecomark, RCS, Oeko-Tex 100 and Reach.

As Stoll notes, locally sourced 100 per cent post-consumer rPET products offer a low-carbon footprint and closed loop solution. Deja is 100 per cent recyclable at the end of use and can be repeatedly re-processed without harmful emissions or discharges to create new high value-added products.

CO2 Dyeing

The next stage in the process sees the Deja recycled yarn dyed with the innovative, supercritical Carbon Dioxide textile dyeing technology from Dutch company DyeCoo at its CleanDye factory.

DyeCoo has developed, optimized and commercialised the use of Carbon Dioxide to dye fabrics over the last 10 years, technology which is also now applicable to dyeing yarns.

The company describes itself as the world’s first commercial supplier of water-free and process chemical free dyeing systems for polyester textiles. The sc-CO2 dyeing machines can dye yarns or fabric rolls in a closed-loop process without using water and process chemicals, thereby avoiding the production of any wastewater. Energy consumption is also reduced significantly when compared to traditional dyeing methods.

By using only the pure non-toxic Corangar dyestuff made by Colourtex, in combination with sc-CO2 that is 95 per cent reclaimed in the machine, the textile dyeing process has less of an environmental impact compared to traditional dyeing technologies. As Carbon Dioxide has the same quality every day and over the whole world the technology is reliable and reproducible, says DteCoo.

Design

The sustainable product advantages achieved through the use of Deja recycled polyester and CO2 dyeing technology are then further enhanced at the design and production stage.

Easy Mask is regarded as a fresh approach to reinterpret a traditional medical facemask from a design perspective.

It is knitted on a Stoll CMS 530 HP B E 7.2 machine, but can also be knitted on other types of the company’s technology, allowing for flexible, local production independent of the machine park.

It is a 3D knitted and playful kinetic object that expands and collapses easily. It is simple to use and comfortable to wear; be it over the face or around the neck. The design approach allows customization, on-demand production, and reduces production waste to below 1 per cent. Integrated ventilation increases breathability and although it does not protect the wearer from infection, it does limit the spread of viruses.

Both the production method, as well as the design itself, takes environmental and sustainable aspects into account. The seamless production method eliminates cut and sew and reduces waste material whilst offering customized, on-demand production to lessen product surplus. Washing at 60°C makes repetitive use possible while all of the mask components (metal bar, knitted strings and adjustment tube) can be easily removed and re-used for other masks.